It’s Not Just Preprocessing

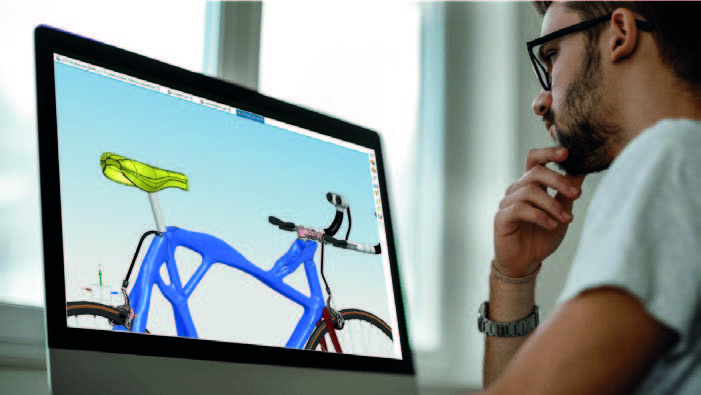

Meshing software in Washington, DC often gets treated as a throwaway step in simulation workflows. But engineers know better. A good mesh is foundational. Without it, even the most advanced solvers can’t provide meaningful or reliable results. From building structural models in Simcenter 3D to simulating airflow in STAR-CCM+, Siemens tools treat meshing as a first-class element in the engineering process—not an afterthought.

The Engineer’s Tradeoff

Automation is great—until it isn’t. Teams in Washington, DC and across the country who are working on complex multiphysics projects need to decide where to sacrifice detail and where to preserve it. Siemens meshing software allows engineers to refine just the regions that matter. Boundary layers in CFD? Fillets in structural models? Thin walls or welds? You decide. The tools won’t do it for you—but they’ll help you do it right.

Engineers who skip these decisions or accept default settings often find themselves rerunning simulations, questioning results, or struggling with solver stability. A little care up front saves hours—or days—down the line.

Meshing for Coupled Simulation

Many systems can’t be analyzed in isolation. A mesh must support thermal gradients, fluid shear, and structural deformation—all in one model. That’s why meshing software must integrate smoothly across simulation tools. For engineers juggling these conditions in high-performance environments, having flexible, reliable meshing software is essential.

SDA Software helps engineers in Washington, DC, and nationwide solve hard problems with the right simulation software, with no unnecessary complexity. Visit www.sdasoftware.com or reach us at 1-703-935-2832 to see how we support your team with Simcenter FEA, CFD, and meshing software solutions.