In modern manufacturing, precision and reliability are essential for product quality and safety. Advanced non-destructive testing (NDT) techniques are critical in aerospace, automotive, electronics, and medical devices, where hidden flaws can compromise performance. To meet these demands, many professionals worldwide are turning to Microfocus X Ray Source India, a trusted solution for advanced imaging capabilities that reveal even the most minor imperfections in complex components.

The Role of Microfocus X Ray Source India in Industrial Inspection

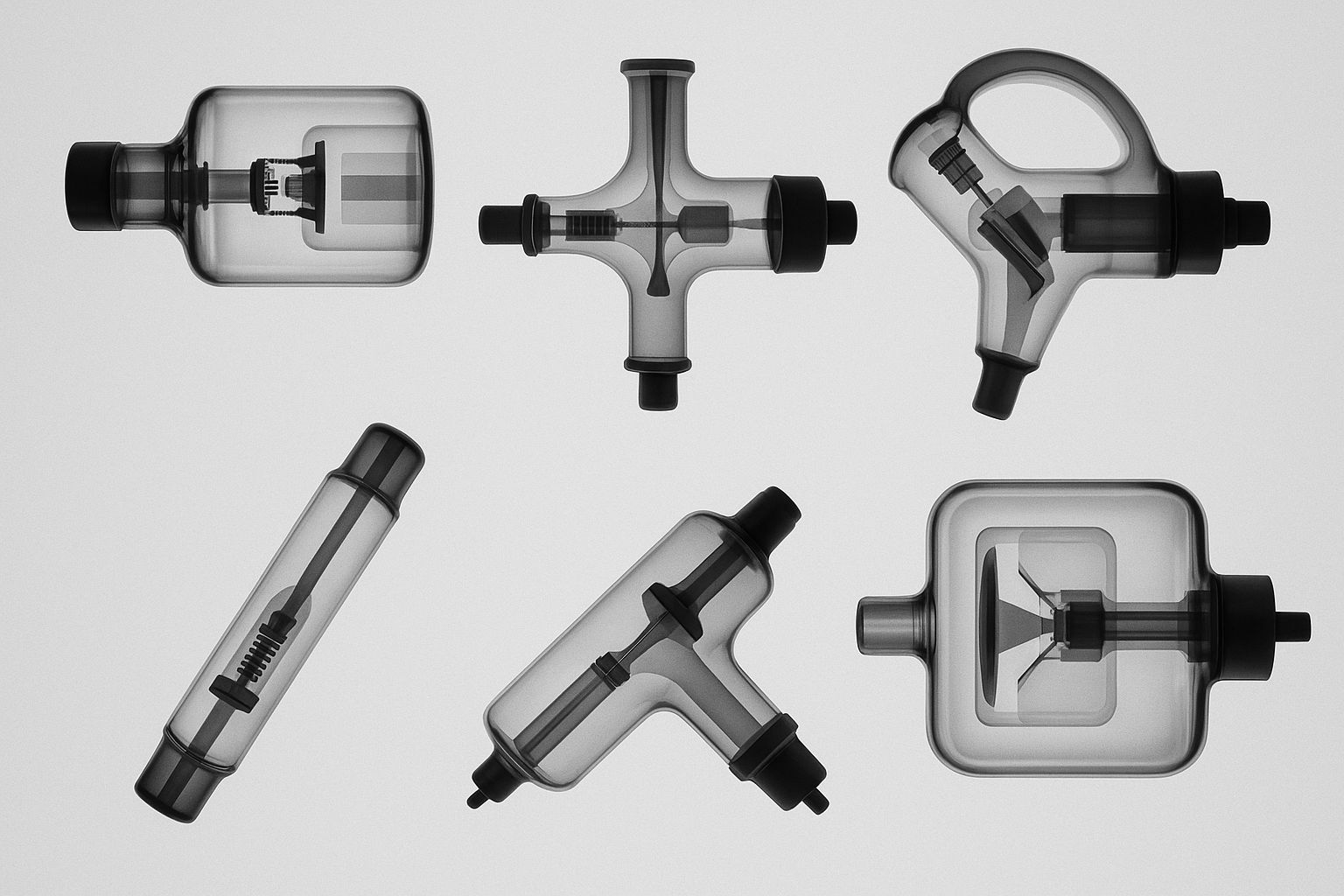

Microfocus X Ray Source India has become a leading choice for businesses seeking to upgrade their inspection systems. Renowned for delivering high-resolution images with exceptional clarity, this technology makes it possible to evaluate intricate assemblies and micro-components with unmatched accuracy. Unlike conventional systems, microfocus sources generate a much smaller focal spot, enabling the detection of tiny cracks, voids, or structural inconsistencies that could otherwise go unnoticed.

Key Benefits of Microfocus X Ray Source India

- Enhanced Image Resolution: The small focal spot produces sharper images, allowing detection of micro-level cracks, voids, and inclusions.

- Non-Destructive Evaluation: Components can be analyzed without damage, preserving usability and reducing waste.

- Increased Throughput: Automated systems with microfocus sources accelerate quality checks, supporting high-volume production.

- Versatility: Effective across metals, ceramics, plastics, and composites, making it ideal for multiple industries.

Applications Across Global Industries

Microfocus X Ray Source India is transforming inspection processes across diverse sectors:

- Aerospace: Verifies turbine blades, welds, and electronic assemblies where safety is critical.

- Automotive: Inspects engine parts, airbags, and electronic units to ensure performance and compliance.

- Electronics: Examines printed circuit boards (PCBs), solder joints, and microchips, supporting the trend toward miniaturization.

- Medical Devices: Ensures the quality of implants, catheters, and other precision components under strict regulatory standards.

Best Practices for Implementation

For companies integrating Microfocus X Ray Source India into their inspection workflows, the following steps can maximize success:

- Assess Inspection Requirements: Match resolution and throughput to product complexity and volume.

- Invest in Training: Equip staff to interpret high-resolution images and safely operate systems.

- Regular Maintenance: Schedule calibration and servicing to sustain performance.

- Collaborate with Experts: Collaborate with experienced providers for customized solutions.

Micro X-Ray Inc. — A US-Based Manufacturer Serving Global Markets

Headquartered in Santa Cruz, California, Micro X-Ray Inc. is a leading US manufacturer of advanced X-ray tube technology, including packaged, microfocus, and mini-focus systems. The company serves industries worldwide, including India, with imaging solutions designed for precision, compliance, and efficiency.

By combining American engineering excellence with global service reach, Micro X-Ray Inc. connects facilities in India and beyond with cutting-edge microfocus X-ray sources that elevate inspection accuracy, reduce risk, and support operational excellence.